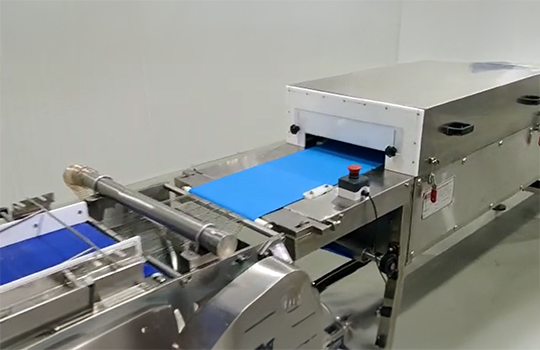

PU COOLING TUNNEL

PU COOLING TUNNEL

VEC- Cooling tunnels are designed for cool the product out from chocolate enrober after coating.

- Made with heavy duty stainless steel tubes and sheets.

- Cooling tunnels are made from 300mm wide to 1500mm wide belts.

- Product Travel Direction : Left to Right or Right to Left

- Total length of cooling tunnel as per product out put.

- Cooling tunnel filled with good insulation to keep the good temp inside the tunnel.

- FDA approved Food grade PU conveyor belt.

- Conveyor return belt also run in cooling chamber. No exposure to ambient temp.

- Automatic pneumatic belt tensioning system it increase the belt life.

- Telescope extensions on both ends on customer request.

- The system will be provided with a scrapper knife at the run out with a catch tray.

- Automatic Centre tracking of the PU belt with pneumatic tracking system

- Cooling zone built with multiple cooling systems to maintain the temperature: +5 to +8°C.

- The construction of the tunnel will be friendly towards maintenance by providing open able tunnels, lifting on one side with supporting hook.

- Requirements : Pneumatic Air with 8kg Pressure, 16cfm.

| Cooling Tunnel | 550 | 650 | 1050 | 1250 | 1550 |

|---|---|---|---|---|---|

| Speed (Meter / Minute) | Upto 3 | Upto 5 | 1 - 6 | 0 - 4 | Upto 8 |

| Main Drive Power (kw) | 0.75 | 1.5 | 2.2 | 2.2 | 2.2 |

| Cooling Capacity | 2 x 3TR | 2 x 5TR | (2 x 5TR) | 3 x 7.5TR | 4 x 7.5TR |

| Power (kw) 415V, 3-phase, 50Hz | 8.5 | 12.5 | 25.45 | 30 | 37 |

| Air Requirement | 6-8 kg / cm2 | 6-8 kg / cm2 | 6 kg / cm2 | 15CFM, 8 kg | 15CFM, 8 kg |

| Outside Dimensions L x W x H (mtr) Approx. | 17 x 1.00 x 1.23 | 12.4 x 1.05 x 1.23 | 15 x 1.55 x 1.23 | 25000mm x 1650mm 1200mm | 40000mm x 2050mm 1200mm |

| Product Inlet Height max | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm |